Put a Rodless Air Cylinder to Work in Tight Spots

Plenty of people on the factory floor are running out of elbow room but still needing speed and dead-on accuracy. Whenever those folks try to cram a regular pneumatic cylinder into a compact machine, the barrel often refuses to fit. Sliding into that gap, the rodless air cylinder packs a long stroke into a body no wider than a lunchbox, and it does so without any moving rod sticking out.

In the paragraphs ahead, we’ll comment on how these cylinders actually work, list a few of the perks they offer, and explain why the choice of supplier can make or break a build. Even little decisions about who sells the parts can ripple out and knock the whole system out of kilter.

Rodless Cylinder, No Rod Required

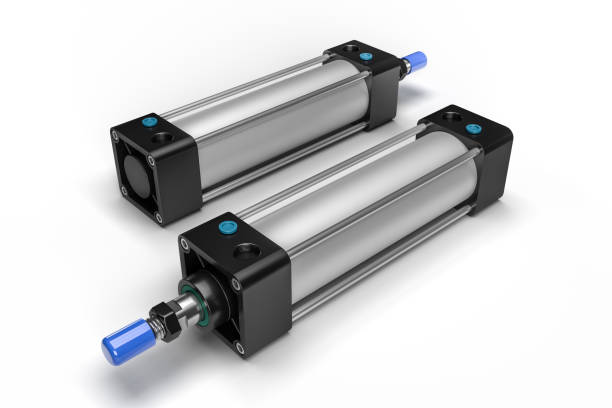

A rodless air cylinder is a pneumatic gadget that scoots stuff around while keeping its footprint almost flat. Picture a regular cylinder where the piston shoots a metal rod out the front; now imagine that rod disappears into the design. Inside, two pistons slide in tandem with an external carriage, and that carriage drags the load along the tube. Because nothing pokes out during the stroke, you get a full-range push or pull without pinching your assembly space.

Manufacturers usually offer rodless cylinders in two big styles:

- Mechanically coupled: In this version, a piston is bolted right to the carriage through a slotted tube. A sturdy sealing band keeps everything tight.

- Magnetically coupled: Here, strong magnets do the linking. Because nothing sticks out the sides, the entire mechanism stays sealed off from dust and moisture.

Engineers love the design whenever they need a long stroke but don’t have headroom to spare. Packaging lines, materials-handling setups, and fast-paced robots all prove rodless cylinders can keep moving without hogging space.

Why Rodless Air Cylinders Rule Tight Spaces

Any modern automation project is trying to move more while standing still, footprint-wise. That goal is where rodless cylinders shine most.

Saves Physical Room

A rodless cylinder only eats up the length of its stroke; no rod sticks out when it retracts. Classic styles need double that room, so cramped machines quickly run out of real estate if they stick with tradition.

Long Travel, No Wobble

A standard rod cylinder starts bending after a few meters; engineers know that headache all too well. Rodless designs shrug off the distance, routinely hitting 5 meters of clean, accurate travel-and a lot farther without falling apart.

Integrated Load-Carrying Ability

Almost every modern rodless cylinder now comes with a load-bearing carriage already built in, letting it shoulder and shuffle a payload all by itself. That one-piece look slashes the need for extra guiding rails and makes life easier for anyone sketching out a new machine.

Improved Aesthetics and Safety

Because handle bars and other bits don’t poke out, these cylinders trim the clutter off a control panel and cut down on snag hazards in busy plants. The closed body also keeps the inside from getting gritty with dust and chips.

Manufacturers and buyers usually lean on veteran automation components suppliers to snag a rodless actuator that matches the voltage, pressure, and stroke length of the job at hand.

Applications of Rodless Air Cylinders in Industrial Automation

Shaped like steel sausages and honest about their appetite for compressed air, rodless cylinders sneak into all kinds of factory work that balks at the word bulky.

Material Handling and Conveying

Line technicians love them for shoving cases down a narrow conveyor lane because one long barrel beats grafting tiny motors onto every zone. A single long-stroke cylinder can marry two moves into one slide, traveling farther than its own length without trembling.

Packaging and Labeling Equipment

Packaging floors get crowded fast, so a compact actuator really saves the day. Rodless cylinders slip into tight corners and handle sealing, clamping, or lining up products without breaking a sweat.

Printing and Textile Machines

In the printing and textile world, motion needs to feel almost glass-smooth. Rodless cylinders drag print heads, keep tension on rollers, and guide yards of fabric exactly where they belong.

Robotics and Pick-and-Place Systems

Pick-and-place stations rely on reach, but that extra length can clutter the base. A rodless cylinder shuttles the gripper sideways without stretching the robot’s footprint, letting operators pack more gear in.

Electronics Assembly

Cleanrooms tolerate very little dust, and every millimeter counts when chips or sensors slide by. Rodless units glide over long spans with the tidiness and accuracy electronics lines demand.

Knowing that, it pays to call a seasoned automation components supplier. They’ll match the cylinder to the load, the speed, the weather inside the booth, and the stroke distance you’re actually using.

Key Considerations for Selecting a Rodless Cylinder

Picking a rodless cylinder is not an Olympic tryout for longest reach. Load ratings, duty cycle, seal material, and rail stiffness quietly separate the winners from the also-rans.

Stroke Length and Load Requirements

First things first: figure out how far the piston has to trudge in and out. If the cylinder isn’t made for those miles-or for the push-and-pull weight you have-it could start grinding, leaking, or outright breaking long before you’ve paid it off.

Speed and Cycle Rate

Next, pin down the speed that keeps the line moving. Some cylinders love a quick-fire rhythm, while others thrive at a slower crawl under serious poundage. Choose the one that matches the heartbeat of your task.

Mounting and Orientation

Rodless tubes aren’t picky about stance; they can lie flat or stand tall, mostly. Still, if gravity tries to bend one the wrong way, you’ll need extra brackets or rails to keep everything honest, so double-check your layout drawings.

Environmental Conditions

Dust, dripping water, furnace heat-you name the hazard, there’s usually a seal or finish that can shrug it off. Ask your supplier for blow-molded seals or IP-rated skins that match the mess you’re working in.

Maintenance Access

Breakdowns happen; the question is how easily you can reach the guts of the cylinder. Modular designs swap parts in a coffee break, while glued-together models may demand a full teardown. Keep servicing time in your calendar.

Supplier Advantages

Buying from a seasoned automation-components supplier saves more than just shelf space: you get tech advice, up-to-date data sheets, neat CAD models, and swap parts that ship on the double. That kind of backup trims your engineering clock and lets production run on schedule.

Why Work with a Trusted Automation-Parts Supplier?

Buying a rodless air cylinder from a reliable distributor isn-t just about the part itself; it-s about the whole package.

- Expert advice: On-site engineers help pick the right size, blend in sensors, and mesh with your existing setup.

- Inventory availability: Well-stocked warehouses mean same-day shipping that keeps your line running.

- Product range: One stop offers mini, standard, and heavy-duty models for every task on your plate.

- Customization: Stroke lengths, carriage shapes, and control interfaces can be tweaked to match your drawings.

- Support services: Manuals, video tutorials, and real people on the phone guide you after the sale.

In short, a carefully chosen automation-components supplier serves up a rodless air cylinder that streamlines motion, handles tight spaces, and stays dependable for years.

Conclusion

Manufacturers who crave long travel without a bulky profile are putting rodless air cylinders front and center. The parts fit effortlessly into packaging lines, conveyor upgrades, and the latest robotic cells because they are compact yet powerful.

Unlocking that potential almost always depends on teaming up with a supplier that knows automation inside and out. Experienced partners deliver precision parts on time, back them with solid support, and help your project cross the finish line early.

Pick the right rodless cylinder for the job, mount it the right way, and you’ll suddenly notice that machinery moves quicker, takes up far less space, and, just as important, does the whole job with fewer safety worries.